Diameter and tolerance

How to measure wire diameter correctly

The wire diameter should always be checked before installation. Measure on a straight section of the wire. Two sections with a minimum distance of one meter should be measured. At each point, two measurements should be taken with a 90-degree offset from each other. The average between the two measurements should comply with the tolerance described in the tables below.

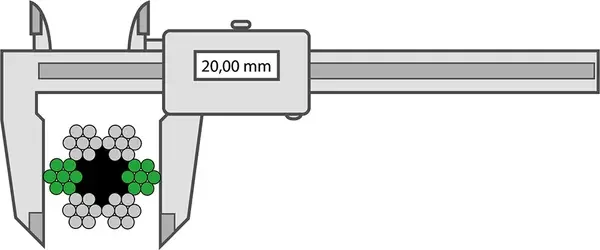

Correct way of measuring

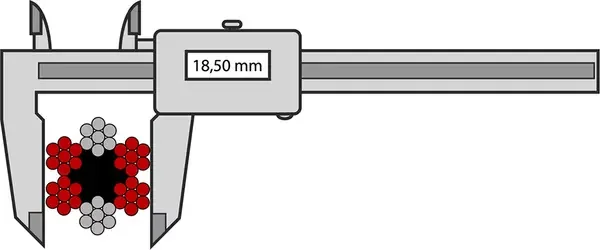

Wrong way of measuring

Steel wire ropes for general applications

| Nominal Rope Dia (mm) |

Percentage (%) |

|---|---|

| 2 to <4 | 0 +8 |

| 4 to <6 | 0 +7 |

| 6 to <8 | 0 +6 |

| 8 and up | 0 +5 |

Tolerance of nominal diameter on unloaded rope.

| Nominal Rope Dia (mm) |

Rope with strands that are exclusively of wire max. % |

Rope with strands that incorporate fibre centres max. % |

|---|---|---|

| 2 to <4 | +7 | - |

| 4 to <6 | +6 | +8 |

| 6 to <8 | +5 | +7 |

| 8 and up | +4 | +6 |

Tolerance of nominal diameter by unloaded rope.

Steel wire ropes for person elevators

Tolerance for nominal diameter for ropes with fiber/synthetic core.

| Unloaded | Loaded to 5% of min. breaking load |

Loaded to 10% of min. breaking load |

|

|---|---|---|---|

| Nominal Rope Dia (mm) |

max. % | min. % | min. % |

| =10 | +6 | +1 | 0 |

| <10 | +5 | +1 | 0 |

Tolerance for nominal diameter for ropes with steel core.

| Unloaded | Loaded to 5% of min. breaking load |

Loaded to 10% of min. breaking load |

|

|---|---|---|---|

| Nominal Rope Dia (mm) |

max. % | min. % | max. % |

| =10 | +3 | 0 | -1 |

| <10 | +2 | 0 | -1 |

Difference between two measurements expressed as percentage of nominal diameter under a load equivalent to 5% or 10% of min. breaking load.

| Nominal Rope Dia (mm) |

Rope ovality max. % |

Average diameter variation max. % |

|---|---|---|

| <8 | +4 | +3 |

| 8 and up | +3 | +2 |

Do you wish to know more about our Lifting KnowHow? Please reach out.

For faster response, call us directly at +47 66 79 95 00!

Composition of steel wire ropeLearn more about the composition of steel wire rope. |

Learn more |

Diameter and tolerance of steel wire ropeLearn more about tolerance of steel wire rope. |

Learn more |

Discarding of steel wire ropeLearn more about the correct ways of discarding steel wire rope. |

Learn more |

Factors to consider when selecting your wire ropeLearn more about how to choose the right steel wire rope. |

Learn more |

Installation of steel wire ropeLearn more about installation of your steel wire rope. |

Learn more |

Technical description of steel wire ropeLearn more about steel wire rope applications. |

Learn more |