Factors to consider when selecting your wire rope

How can I ensure the right steel wire rope selection? We've compiled a table of 10 essential questions below to assist you in determining the most suitable steel wire rope for your specific requirements. Opting for the correct steel wire rope ensures maximum service life, provided regular inspection and proper lubrication are maintained.

Choosing your steel wire rope

When placing an order for a new steel wire rope, ensure that you consider the appropriate type, construction, dimensions, and length. Adhere to the recommendations of the machine manufacturers and verify that the equipment aligns with the correct machine group/grade.

WARNING! Choosing the wrong steel wire rope may lead to a reduced working life, rope fractures, and/or equipment damage.

The following questions can guide you in selecting the right construction of the steel wire rope. In case of conflicting answers, opt for the most frequently occurring alternative. Combining the answers to these ten questions will assist in choosing the most optimal wire rope construction, although additional questions or considerations may sometimes point to a different wire rope construction.

| Questions | Yes | Yes and No | No |

|---|---|---|---|

| Is freedom of rotation required? | Choose low-rotation wire rope | Choose low-rotation wire rope | 6, 8, 9 and/or 10-cord wire rope |

| Is a high breaking strength required? | Special steel rope, compacted | Steel rope with steel core | - |

| Are there many bends in the operation? | Multi-strand steel rope with small outer threads | Multi-strand steel rope with small outer threads | - |

| Should the wire rope withstand heavy external wear and tear? | Soled rope with coarse outer threads | Steel rope with coarse outer threads | - |

| Spooling of steel rope in several layers? | Strong wire rope, compacted | - | Cross-braided wire rope |

| Is there a risk of deformation damage | Steel rope with fiber in the steel core | Steel rope with fiber in the steel core | - |

| Left spool drum? | Right-handed wire rope | - | Left-turned wire rope |

| Left-handed wire rope steering? | Right-handed wire rope | - | Left-turned wire rope |

| Is there a corrosive environment during the operation? | Galvanized/stainless steel rope | Galvanized/stainless steel rope | Galvanized/bright wire rope |

For further guidance, please contact us.

Rotation resistance

To minimize rotation, especially with high lifting heights, use "rotation-resistant" or "Low Rotation" ropes. Rotation-resistant ropes consist of multiple layers of strands, with each layer laid in the opposite direction to the next, balancing torque forces within the rope.

Definitions of breaking load

Minimum Breaking Load (MBL)

The minimum breaking force (MBL), in kilonewtons, is the lowest breaking strain of the rope when tested to destruction.

Calculated breaking load

This value is calculated from the product of the sum of the cross-sectional metallic areas of all individual wires in the rope and the tensile strength grade(s) of the wires. The total metallic area is directly proportional to the square of the nominal diameter of the rope. A standard spinning loss factor, resulting from the twisting of strands and wire, is then applied.

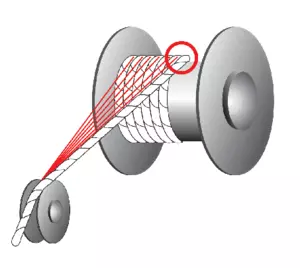

Fleet angle

An excessively large fleet angle can cause excessive wear of the rope against the adjacent flange on the drum, potentially leading to torsional problems.

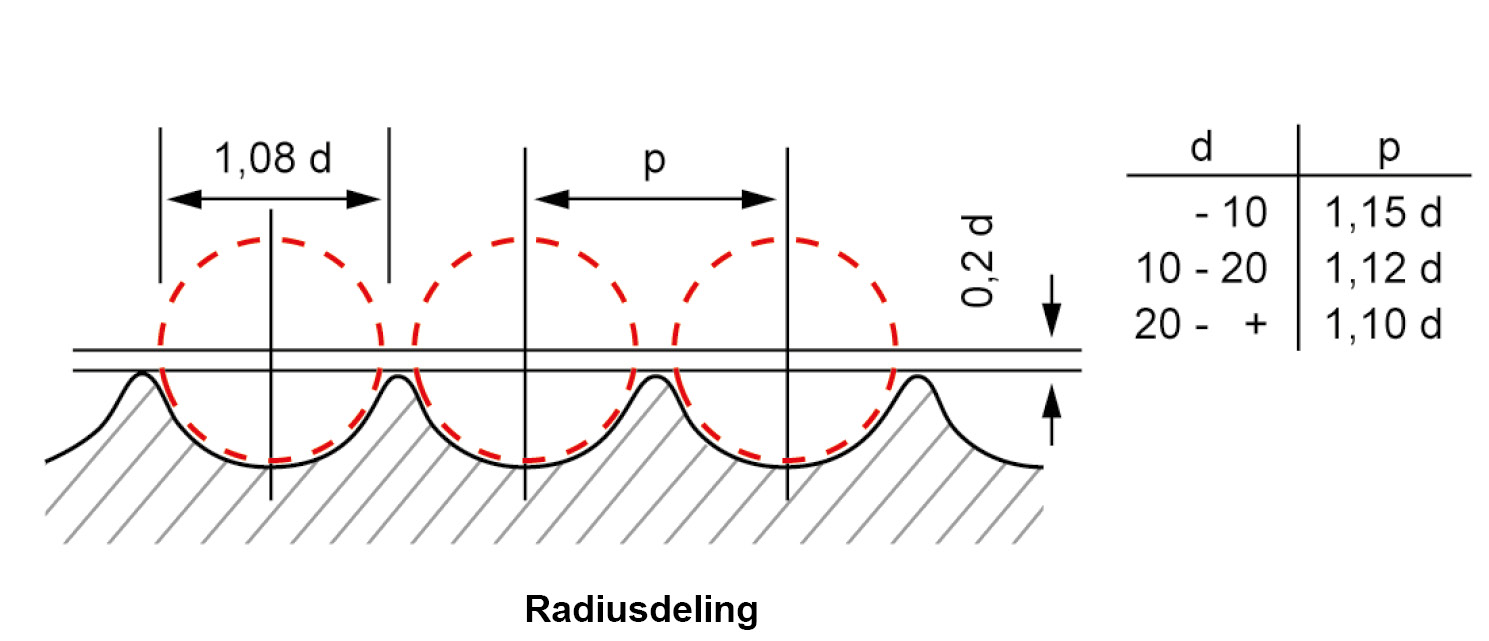

Wire rope sheaves

Wire rope sheaves should support the rope along approximately one-third of its circumference. Certex Norway AS recommends a groove diameter of 1.08 x d, where d = nominal wire rope diameter.

Before installing a new rope, check the sheave grooves, layers, and lubrication. Measure the groove diameter with a radius gauge, ensuring it falls within the range of nominal rope diameter +8% to +14% (0.54 x d to 0.57 x d).

WARNING! Worn sheaves should be replaced/refurbished.

|

|

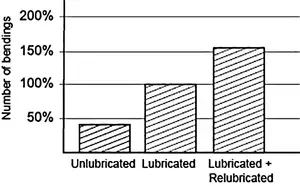

Maintenance - lubrication

| During operation, steel wire rope wires experience wear against each other. Lubrication during manufacturing improves the rope's function and increases its lifespan. Check the lubrication immediately after installation, clean the rope from inappropriate materials, and, if necessary, complete the wire rope with lubrication before use. It's crucial to lubricate the rope at regular intervals based on valid operational conditions. |  |

WARNING! An unlubricated or incorrectly lubricated wire rope significantly shortens its lifespan.

Do you wish to know more about our Lifting KnowHow? Please reach out.

For faster response, call us directly at +47 66 79 95 00!

Composition of steel wire ropeLearn more about the composition of steel wire rope. |

Learn more |

Diameter and tolerance of steel wire ropeLearn more about tolerance of steel wire rope. |

Learn more |

Discarding of steel wire ropeLearn more about the correct ways of discarding steel wire rope. |

Learn more |

Factors to consider when selecting your wire ropeLearn more about how to choose the right steel wire rope. |

Learn more |

Installation of steel wire ropeLearn more about installation of your steel wire rope. |

Learn more |

Technical description of steel wire ropeLearn more about steel wire rope applications. |

Learn more |