Installation of steel wire rope

How to use your new steel wire

Install your new steel wire correctly for safe use and to avoid damaging your product. Here you will find tips on how to unwind the steel wire from the packaging, advice on connection and running-in, and how to cut the steel wire if necessary.

It is important to handle your steel wire correctly to avoid damaging it during unpacking and installation. Read and see our advice and guidance on how to unwind the wire from the packaging you received it in, how to shorten or cut your steel wire, running in the steel wire, and coupling between two steel wires.

Before you begin unpacking your wire, you should have a procedure for installing the wire, which must be carried out in accordance with a detailed plan issued by the user of the steel wire.

When releasing the wire end from the supply spool after removing the packaging, this should be done in a controlled manner. When releasing ties or securing the wire end, the wire tends to straighten out, and unless this is controlled, it can result in serious personal injury.

Wire delivered on a spool

The wire spool should be placed on the ground and unrolled straight, ensuring that it does not get dirty from dust, gravel, moisture, or any other harmful material.

The wire should never be pulled up over a stationary spool, as this will cause twisting of the wire, which can lead to kinks. If the spool is too large to handle physically, it should be placed on a turntable, which allows unrolling the wire by pulling on the end of the wire and pulling away from the spool.

Correct methods for unrolling wire from a spool are shown in the video above.

Wire delivered on a drum

An axle of sufficient strength must be passed through the hole in the drum, and it should be placed on a suitable stand that allows the drum to rotate and provides the option to hold back on the drum to prevent overrun during unwinding/installation.

For multi-layer winding, the wire drum should be placed in equipment that enables back tension of the wire/reel as it is wound from the supply drum to the spool. This should ensure that the underlying layers of wire, especially the innermost layer of wire, are wound so tightly that they have full contact with the drum or the underlying layer of wire.

The supply drum should be positioned so that the wire guiding angle is kept as small as possible against the drum (maximum 1.5°). This can be achieved by placing the stand with the supply drum as far away from the winding drum as possible. If a bend forms in the wire, it must not be tightened to the point of forming a kink.

The drum stand must be securely mounted to prevent reverse bending during winding (S-shape), i.e., for a drum with upper winding wire, the wire should be taken from the top of the supply drum.

Warning! The supply drum is not specifically designed for winding with tension and may not be strong enough! If tension winding is required, the wire should be ordered on a drum that is strong enough for the purpose.

Otherwise, winding can be performed by suspending the wire drum from a crane hook. The hook should be lowered to the maximum, a sufficient weight (2.5% -5% of the wire's MBL) should be attached to the hook, and the steel wire should be wound tightly onto the drum.

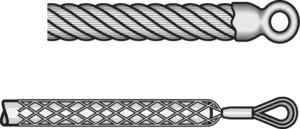

Coupling

If you are installing the new wire using the old one, it can be done by attaching a wire sleeve to the wire ends that need to be coupled together. The open end of the wire sleeve should be securely attached to the wire with a clamp or alternatively with a welded eye.

It is important to reduce the risk of transferring twisting from the old wire to this new one, especially when replacing rotationally weak wires. This can be done by connecting the wires with a fiber rope. Alternatively, the coupling or wire sleeve can be equipped with a swivel, allowing individual rotation between the wires.

Warning! We do not recommend connecting the new and old wire together using welding. This can transfer twisting from the old wire to the new one, and the welding can break, for example, when passing through wire sheaves.

Alternatively, the installation can be carried out with a pilot line consisting of a thinner fiber or steel wire, which is attached to a wire sleeve in the new wire. If a steel wire is used as a coupling, it should be rotation-free or have the same lay direction as the new wire.

Warning! The wire used as a coupling or pilot line must have sufficient strength to withstand the weight of the new steel wire and the stress during installation.

Cutting the wire

If it is necessary to cut the wire, the strands on each side of the cutting point should be secured with clamps. The length of each clamp should be at least 2 times the wire diameter, and the spacing between the clamps should be equal to the wire's diameter.

One clamp on each side of the cutting point is usually sufficient for pre-formed steel wires (see EN 12385-2). For non-pre-formed steel wires, rotationally weak/rotation-free, and parallel-laid wires, a minimum of two clamps on each side of the cutting point is recommended, and the spacing between the clamps should be equal to the wire's diameter.

Cutting should preferably be done with an angle grinder. Other suitable mechanical or hydraulic cutting tools can be used, but are not recommended when the wire end needs to be welded or soldered. During cutting, ensure adequate ventilation to avoid the accumulation of vapors from the wire and its components.

Warning! Certain wires contain synthetic material which, when heated to a temperature higher than normal production temperatures, will degrade and possibly emit toxic fumes.

Wire made of carbon steel wires is not considered to pose a health hazard. During subsequent processing (e.g., cutting, welding, sharpening, cleaning), dust and vapors containing elements that may affect exposed individuals may be produced.

After cutting, improper securing of the wire end can lead to loss of tension or twisting in the wire. An alternative method to cutting is melting and tapering, a process aimed at preventing cords and strands from sticking out.

Running in new wire

|

To increase the lifespan of your steel wire, it is recommended to run the new wire in by slowly running it through the lifting system with a low load (i.e., 10% of the working load limit (WLL)) several times to allow the wire to gradually adapt to the working conditions. The wire should never be run in with full load or even overloaded. Ensure that the wire spools correctly onto the wire drum, that the wire does not slack, or there is no overlap of the wire on the drum. |

|

Warning! Irregular spooling will result in severe surface wear and deformation of the wire.

Do you wish to know more about our Lifting KnowHow? Please reach out.

For faster response, call us directly at +47 66 79 95 00!

Composition of steel wire ropeLearn more about the composition of steel wire rope. |

Learn more |

Diameter and tolerance of steel wire ropeLearn more about tolerance of steel wire rope. |

Learn more |

Discarding of steel wire ropeLearn more about the correct ways of discarding steel wire rope. |

Learn more |

Factors to consider when selecting your wire ropeLearn more about how to choose the right steel wire rope. |

Learn more |

Installation of steel wire ropeLearn more about installation of your steel wire rope. |

Learn more |

Technical description of steel wire ropeLearn more about steel wire rope applications. |

Learn more |