Magnetic Rope Testing

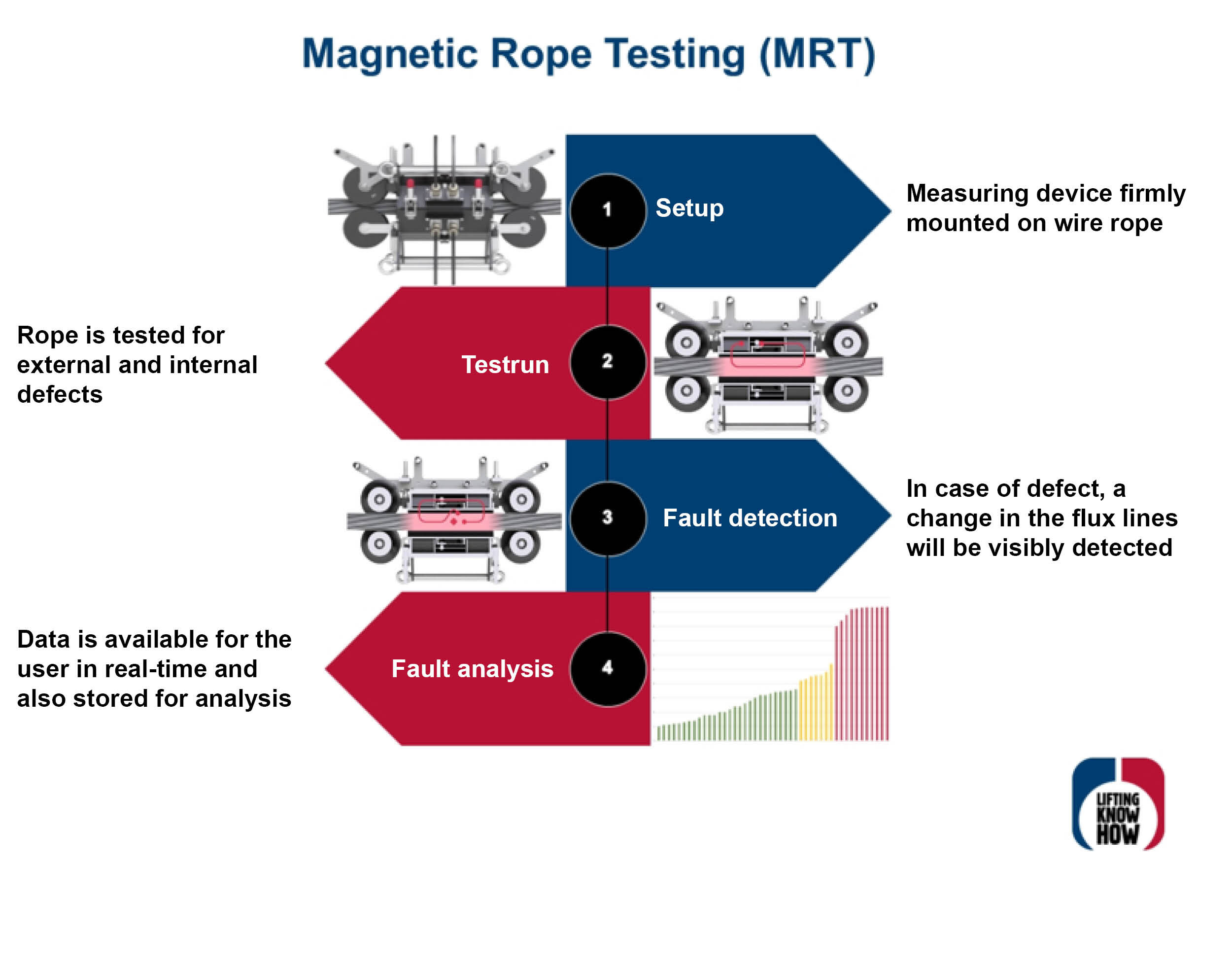

The MRT method is a non-destructive, magnetic and contactless procedure that makes it possible to detect broken wires, distortions and corrosion on steel ropes.

Kontakt oss for MRT service!

Ved å ringe vårt hovednummer, 66 79 95 00, vil du bli møtt av vårt automatiske sentralbord.

- Tast 4 for Service

Tastevalget vil da føre deg direkte til en av våre kundebehandlere.

Send us an email

AMC

Since 2018, AMC Instruments has been part of Axel Johnson, Lifting Solutions Group.

The company acts as a technical partner for the training of qualified and experienced personnel in non-destructive testing for levels 1 and 2 of ISO 9712 - steel cables used for lifting and transporting people and goods, whether by elevator or not.

AMC is constantly introducing innovative innovations to the MRT concept, most recently with an automatic setting in the software that enables full cable inspection after improving the user interface and optimizing the use of magnetism technology.

The MRT method

This magnetic method was introduced in the cable car industry to inspect the transport and transportation system and to identify external and internal defects.

In the 1980s, this technique was expanded to the offshore heavy lifting sector, where there was a growing need for efficient and safe solutions.

In the latest version of the ISO 4309 standard, MRI has been included as an assessment method for inspection of generic heavy steel ropes.

MRT units are equipped with two different signal detectors (on two separate electrical circuits). These warning signals tell the operator about potential damage such as internal and external damaged wires, corrosion, wear, etc.

The LF signal is the main technique in this field, regulated by international standards and consists of measuring

the leakage flux that occurs when a defective part of the rope is inserted into the unit.

Enterprise of CompetenceWe offer professional and certified controls, and can make repairs either from our service vehicles directly on the customer's workplace or in our workshops. |

Read more |

Fall arrest serviceWe have broad specialist expertise and experience in carrying out inspections of fall protection equipment used when working at height. Our service fitters can carry out inspections and service on a range of fall protection equipment. |

Read more |

Magnetic Rope TestingThe MRT method is a non-destructive, magnetic and contactless procedure that makes it possible to detect broken wires, distortions and corrosion on steel ropes. |

Read more |

Maritime serviceWe offer service, testing and inspection on liferafts, survival suits and fire equipment. This equipment should have regular service inspections to maintain necessary certification and warranty. |

Read more |

Mooring analysisA quality supplier with a distribution network along the entire Norwegian coast. In addition to providing products to the aquaculture industry, we also offer our customers mooring analyses in collaboration with our partner. |

Read more |

NDT inspectionWe offer NDT services within the most conventional methods. Our inspectors are certified Level 2, according to EN ISO 9712. Our long experience in NDT inspection of both on- and offshore equipment, ensures top of the line service quality. |

Read more |

Rope Watcher™Rope Watcher™ allows you to take control of your rope inspection in real-time and reduce production downtime while confidently fulfilling the rope inspection criteria. |

Read more |

Technical supportCertex Norge has experienced and qualified operators for spooling, inspections, and control of steel wire ropes, both onshore and offshore. |

Read more |

Your Service PartnerA Service Partner agreement provides the customer with peace of mind, predictability, and increased efficiency, which can contribute to better operations and financial savings. |

Read more |